Butt Welding Steel-plastic Composite Pipe Production Line

This production line adopts continuous welding forming compound process, one step produces steel-plastic composite pressure pipe. It's one of the key popularized science and technology achievement projects by MOC.

Main technical charateristics

This production line adopts continuous welding forming compound process,one step producessteel-plastic composite pressure pipe. Ilt's one of the key popularized science and technology achievementprojects by Moc.

Steel belt precision roller pressure molding process used to ensure stable and continuous welding.Precise synchronization control technology makes each hauling machine works at a uniform speed.

Special argon arc welding machine,welding torch cooling system and double welding torch automaticconversion device are equipped, ensure long-term continuous production.

Adopts continuous welded tube, inner and outer layer of plastic composite extrusion technology to solvethe adheresion of steel tube.

huachuang successes on the brand new connection of steel-plastic pipe.

The extrusion line can be easily modified to produce both butt-weld stainless steel-plastic composite pipeand solid wall plastic pipe.

lt adopts advanced PLC and color LCD touch screen control system for whole extrusion line, singlemachine adjustment, synchronization function realized, failure warning, high degree automatization andstable and reliable production.

Main technical parameters

| Type | Pipe Size(mm) | Max.Speed(m/min) | Total Power(kw) | Total Length(m) |

| PSP-YH63 | Φ20~Φ63 | 10 | 230 | 75 |

| PSP-YH110 | Φ63~Φ110 | 5 | 280 | 85 |

| PSP-YH200 | Φ110~Φ200 | 2 | 300 | 95 |

| PSP-YH315 | Φ200~Φ315 | 1 | 350 | 100 |

WHY CHOOSE US ?

STRENGTH

The group currently has a standard factory area of over 20000 square meters and an annual production capacity of around 100 sets of pipeline equipment

INNOVATION

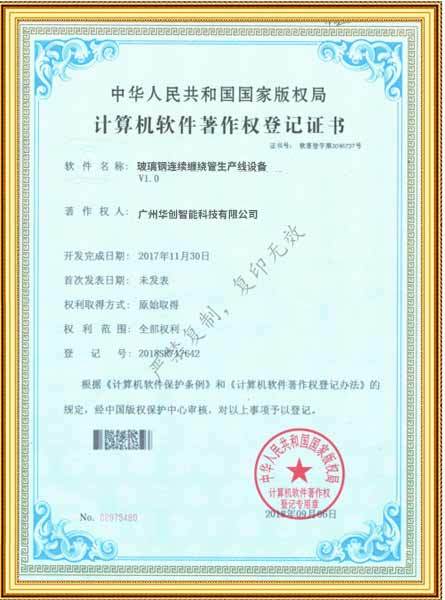

Since its establishment, the company has continuously carried out technological innovation and industrial upgrading, and has been rated as a national high-tech enterprise

SERVICE ASSURANCE

Our company always focuses on customers and strives to improve product quality and service level, with the goal of zero product defects and zero customer complaints

PARTNERS

Our success cannot be achieved without the strong support of every partner

Inquire

Note: Please complete this form, and we will contact you by the next business day.