Fully automatic weld seam tracking system

During the forming process of straight seam pipes, there will be a certain degree of left and right swinging of the weld seam, which requires continuous observation by the human eye and manual adjustment of the welding gun position. The huachuang laser welding seam tracking system can automatically detect deviations in the weld seam and adjust the welding gun position in real time, freeing up manual labor and achieving high-quality, automated welding

Laser welding tracking system:

During the forming process of straight seam pipe, the weld will swing left and right to a certain extent, which requires human eyes to constantly observe and manually adjust the welding gun position. huachuang laser weld tracking system can automatically detect the weld deviation and adjust the welding gun position in real time, freeing up manual work and achieving high-quality, automated welding.

The newly developed straight seam pipe height detection function can avoid the inconsistent length of the leaking part when replacing the tungsten electrode, which leads to the need to adjust the welding gun height again after changing the gun, prolonging the gun changing cycle and causing waste of materials. The straight seam pipe height detection function can complete the straight seam pipe height detection in the gun changing project, and automatically adjust the welding gun descent height according to different heights without manual adjustment.

WHY CHOOSE US ?

STRENGTH

The group currently has a standard factory area of over 20000 square meters and an annual production capacity of around 100 sets of pipeline equipment

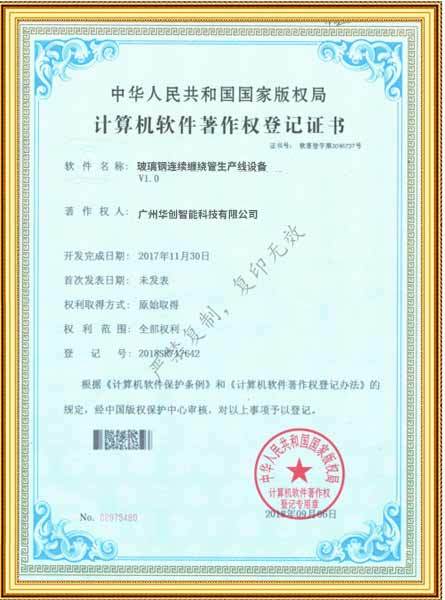

INNOVATION

Since its establishment, the company has continuously carried out technological innovation and industrial upgrading, and has been rated as a national high-tech enterprise

SERVICE ASSURANCE

Our company always focuses on customers and strives to improve product quality and service level, with the goal of zero product defects and zero customer complaints

PARTNERS

Our success cannot be achieved without the strong support of every partner

Inquire

Note: Please complete this form, and we will contact you by the next business day.