SEARCH

A high-tech enterprise specializing in the research, development, manufacturing and service of FRP spiral pipes, plastic pipes, composite pipe production lines, various pipe molds and plastic auxiliary machines

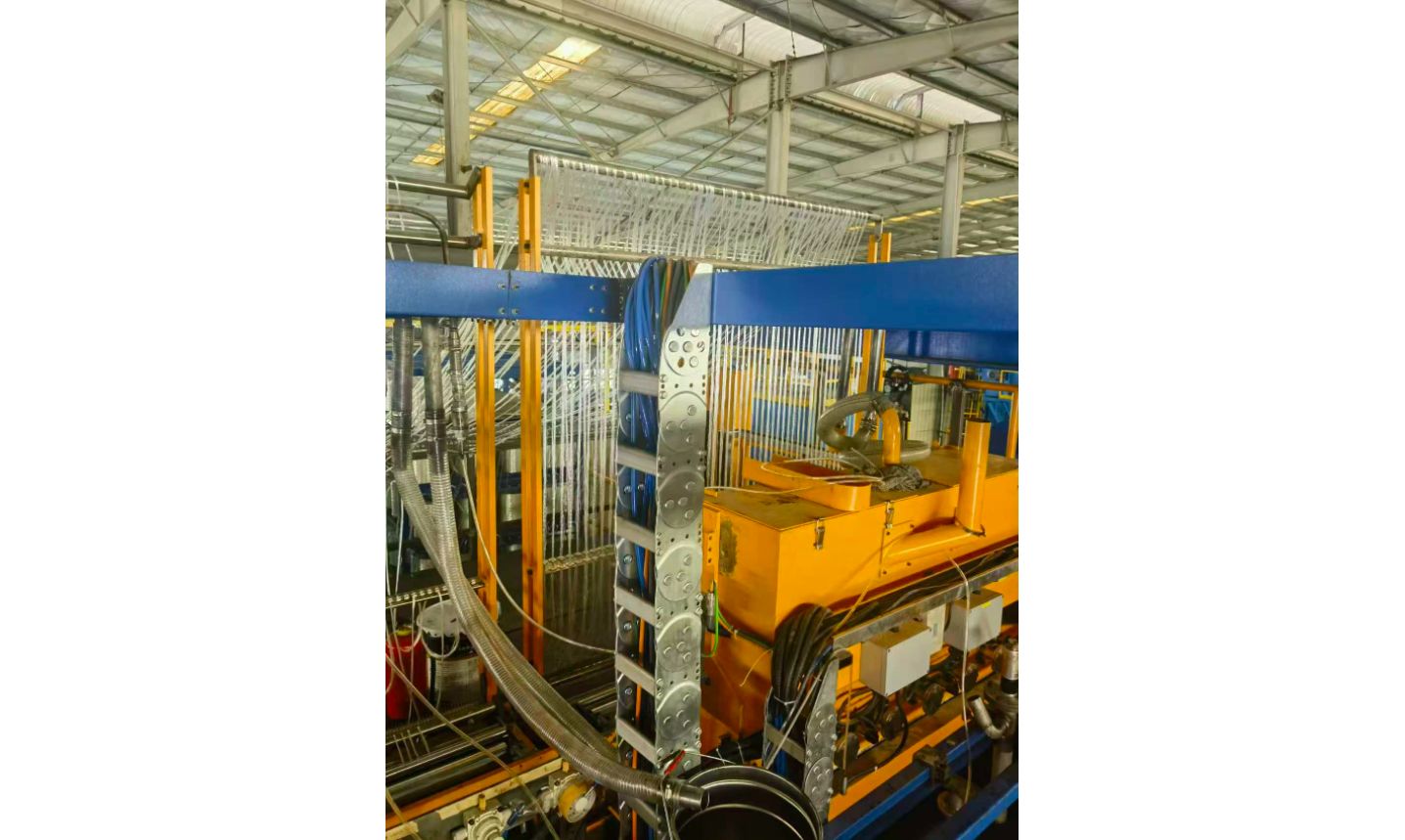

Automated production line for glass fiber continuous winding pipes

Contiuous Fiberglass Winding Machine

Fiberglass Filament Winding Machine

Continuous Pipe Winding Machine

Newest Automated Production Line For Glass Fiber Continuous Winding Pipes

Cheap Automated Production Line For Glass Fiber Continuous Winding Pipes

Quality Automated Production Line For Glass Fiber Continuous Winding Pipes

New Automated Production Line For Glass Fiber Continuous Winding Pipes

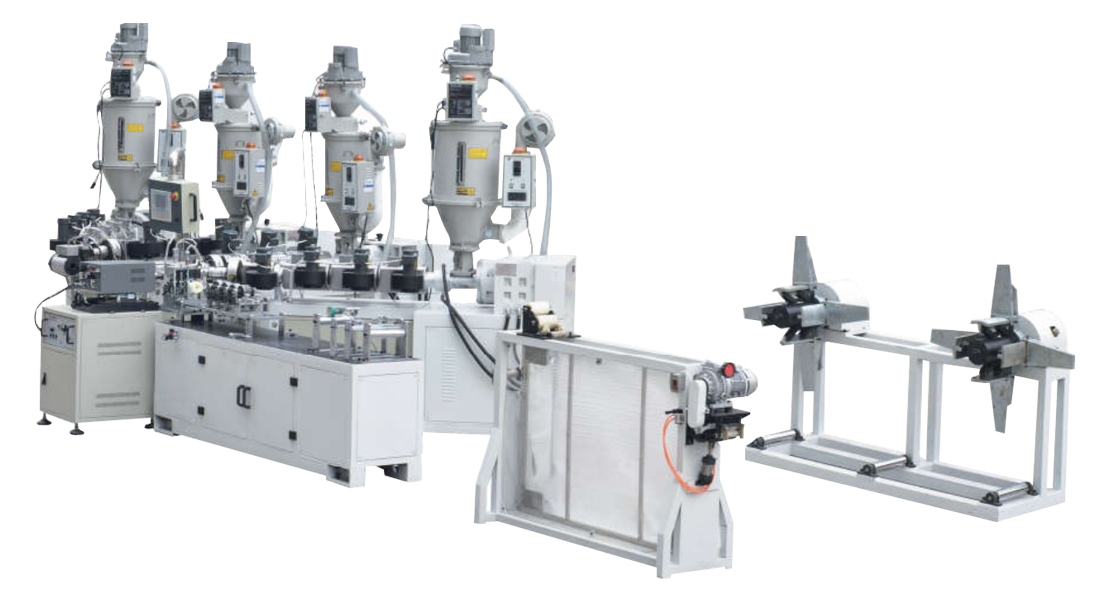

Butt Welding PEX-AL-PEX Composite Pipe Production Line

Overlap Welding PEX-AL-PEX Composite Pipe Production Line

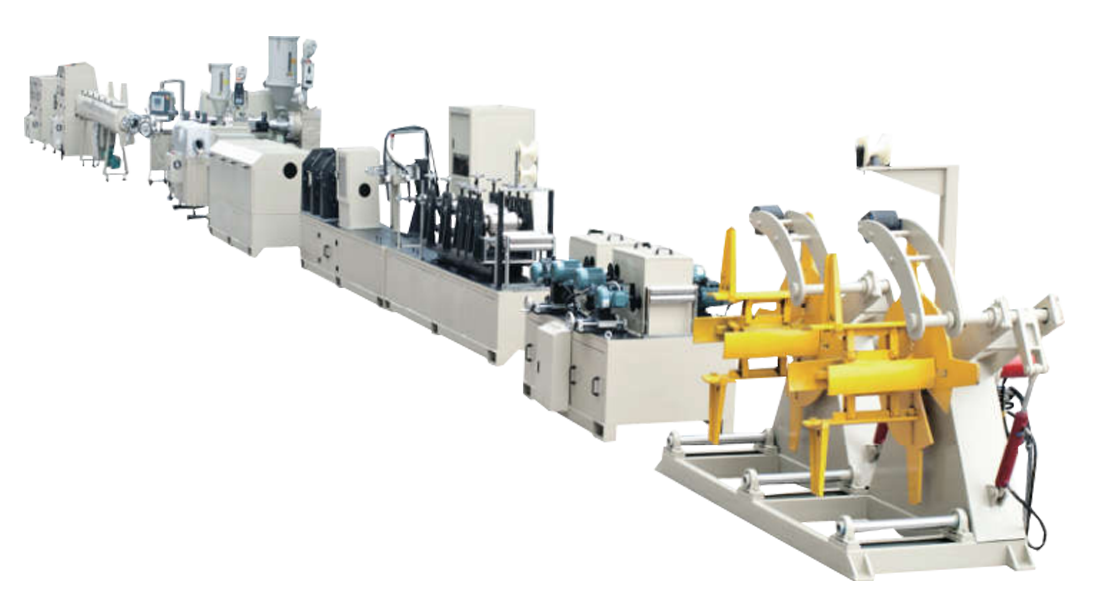

Butt Welding Steel-plastic Composite Pipe Production Line

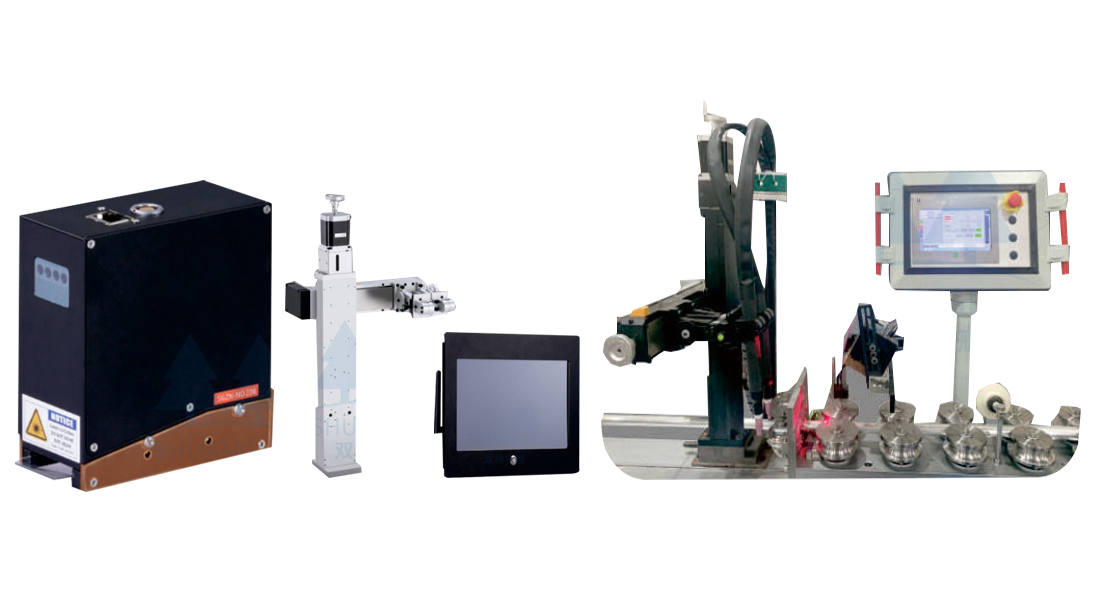

Fully automatic weld seam tracking system