Grp Pipe Cfw Machine

lt adopts high precision passive aluminum on line forming machine with aluminum beam calibration cuttingsystem, on line aluminum storage welding effect testing system, aluminum storage system to guaranteethe high roundness and precise dimensions.

Automated Production Line For Glass Fiber Continuous Winding Pipes:

Introducing the cutting-edge solution for manufacturing efficiency - the Automated Production Line for Glass Fiber Continuous Winding Pipes. This innovative system is designed to revolutionize the way glass fiber pipes are produced, ensuring unparalleled precision, speed, and consistency in the manufacturing process.

At the heart of this automated production line is the state-of-the-art winding technology, which allows for continuous and seamless winding of glass fibers onto the pipe mandrel. This not only significantly increases productivity but also eliminates the need for manual intervention, reducing labor costs and errors. The use of advanced sensors and control systems ensures that the winding process is carried out with utmost accuracy, resulting in high-quality glass fiber pipes that meet strict industry standards.

One of the standout features of our automated production line is its ability to handle large volume orders efficiently. The continuous winding process enables the production of long lengths of pipe without any interruptions, making it ideal for mass production. Additionally, the system is equipped with automatic cutting and trimming mechanisms, further enhancing its efficiency and reducing material waste.

Main technical parameters

| Type | Pipe Size(mm) | Max.Speed(m/min) | Total Power(kw) | Total Length(m) |

| SLTP-YH32 | Φ20~Φ32 | 12 | 180 | 38 |

| SLAP-YH32 | Φ16~Φ32 | 18 | 260 | 56 |

| SLAP-YH32G | Φ16~Φ32 | 30 | 300 | 80 |

| SLAP-YH63 | Φ40~Φ63 | 8 | 300 | 60 |

| SLAP-YH110 | Φ75~Φ110 | 3 | 340 | 85 |

| SLAP-YHR63 | Φ20~Φ63 | 15 | 300 | 65 |

| SLAP-YHR100 | Φ75~Φ110 | 2 | 360 | 85 |

WHY CHOOSE US ?

STRENGTH

The group currently has a standard factory area of over 20000 square meters and an annual production capacity of around 100 sets of pipeline equipment

INNOVATION

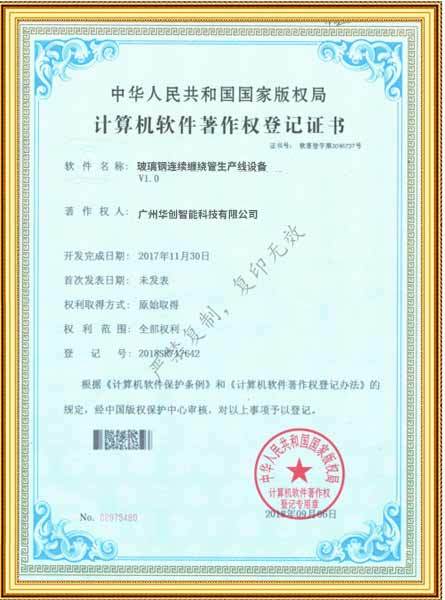

Since its establishment, the company has continuously carried out technological innovation and industrial upgrading, and has been rated as a national high-tech enterprise

SERVICE ASSURANCE

Our company always focuses on customers and strives to improve product quality and service level, with the goal of zero product defects and zero customer complaints

PARTNERS

Our success cannot be achieved without the strong support of every partner

Inquire

Note: Please complete this form, and we will contact you by the next business day.