Filament Winding Machine

The Automated Production Line for Glass Fiber Continuous Winding Pipes features a modular design that enables easy customization and scalability, accommodating various pipe diameters and thicknesses to meet diverse industry requirements. Its user-friendly interface and intelligent monitoring system provide real-time data on production parameters, allowing operators to optimize performance and troubleshoot any issues promptly.

The Automated Production Line for Glass Fiber Continuous Winding Pipes features a modular design that enables easy customization and scalability, accommodating various pipe diameters and thicknesses to meet diverse industry requirements. Its user-friendly interface and intelligent monitoring system provide real-time data on production parameters, allowing operators to optimize performance and troubleshoot any issues promptly.

Incorporating the latest advancements in robotics and artificial intelligence, this production line minimizes human intervention, thereby reducing labor costs and increasing safety. The automated guidance and handling systems ensure precise alignment and placement of the glass fiber during the winding process, while the quality control module employs sophisticated sensors and vision systems to detect even the slightest imperfections, guaranteeing that only pipes of the highest standards leave the production floor.

In conclusion, the Automated Production Line for Glass Fiber Continuous Winding Pipes represents a significant leap forward in pipe manufacturing technology. With its emphasis on automation, precision, customization, and sustainability, this system sets new benchmarks for quality, efficiency, and environmental responsibility in the fiberglass pipe industry. Embrace the future of pipe manufacturing and experience the transformative benefits of our groundbreaking production line.

WHY CHOOSE US ?

STRENGTH

The group currently has a standard factory area of over 20000 square meters and an annual production capacity of around 100 sets of pipeline equipment

INNOVATION

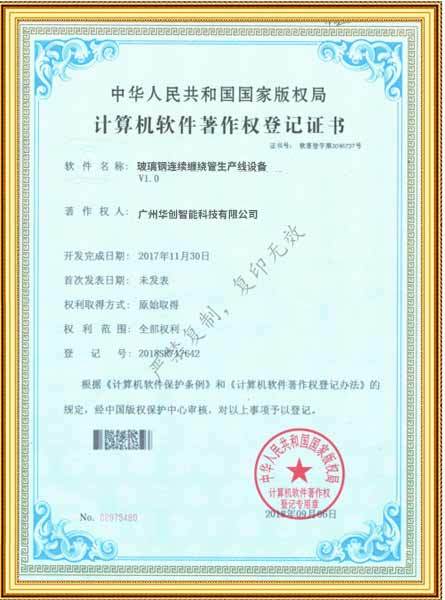

Since its establishment, the company has continuously carried out technological innovation and industrial upgrading, and has been rated as a national high-tech enterprise

SERVICE ASSURANCE

Our company always focuses on customers and strives to improve product quality and service level, with the goal of zero product defects and zero customer complaints

PARTNERS

Our success cannot be achieved without the strong support of every partner

Inquire

Note: Please complete this form, and we will contact you by the next business day.