Fiberglass Filament Winding Machine

lt adopts high precision passive aluminum on line forming machine with aluminum beam calibration cuttingsystem, on line aluminum storage welding effect testing system, aluminum storage system to guaranteethe high roundness and precise dimensions.

Main technical charateristics

lt adopts high precision passive aluminum on line forming machine with aluminum beam calibration cuttingsystem, on line aluminum storage welding effect testing system, aluminum storage system to guaranteethe high roundness and precise dimensions.

Outer layer adhesive and plastic co-extrusion mould design to enhance the AL-PLAS adhesion.

PPR-AL-PPR Butt-welded pipes ,RPAP5 pipes and outer layer welding copper-plastic pipe also can beproduced on this machine only require to make small modification.

This machine adapts PLC control system and liquid touch screen HMl, easy operation,synchronization,alarm and high automation and reliable performance.

Automated production line for glass fiber continuous winding pipes:

The Automated production line for glass fiber continuous winding pipes is a revolutionary manufacturing solution. It incorporates advanced technologies and precise engineering to ensure efficient and high-quality production. The key features of this production line include: high automation, ensuring continuous and smooth operation without the need for excessive human intervention; precise winding technology, guaranteeing the uniformity and strength of the glass fiber pipes; and durability, capable of withstanding various environmental conditions. The glass fiber continuous winding pipes produced by this line have excellent mechanical properties and chemical resistance. They are widely used in industries such as construction, transportation, and infrastructure. The automated process not only enhances productivity but also reduces errors and improves product consistency. With its state-of-the-art design and reliable performance, this production line is a game-changer in the field of glass fiber pipe manufacturing, providing customers with top-quality products that meet their specific needs. It truly showcases the power of advanced manufacturing and the potential of glass fiber continuous winding pipes in diverse applications.

Main technical parameters

| Type | Pipe Size(mm) | Max.Speed(m/min) | Total Power(kw) | Total Length(m) |

| SLTP-YH32 | Φ20~Φ32 | 12 | 180 | 38 |

| SLAP-YH32 | Φ16~Φ32 | 18 | 260 | 56 |

| SLAP-YH32G | Φ16~Φ32 | 30 | 300 | 80 |

| SLAP-YH63 | Φ40~Φ63 | 8 | 300 | 60 |

| SLAP-YH110 | Φ75~Φ110 | 3 | 340 | 85 |

| SLAP-YHR63 | Φ20~Φ63 | 15 | 300 | 65 |

| SLAP-YHR100 | Φ75~Φ110 | 2 | 360 | 85 |

WHY CHOOSE US ?

STRENGTH

The group currently has a standard factory area of over 20000 square meters and an annual production capacity of around 100 sets of pipeline equipment

INNOVATION

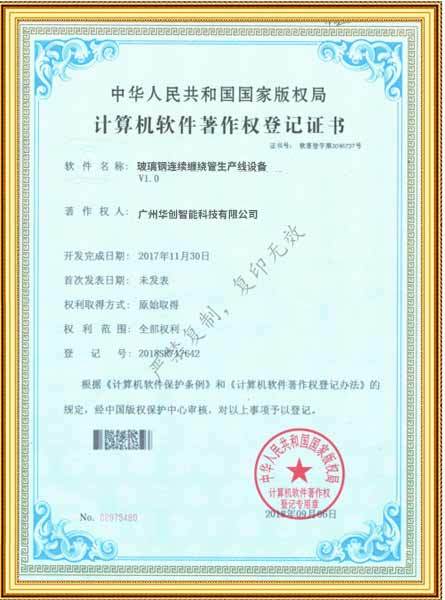

Since its establishment, the company has continuously carried out technological innovation and industrial upgrading, and has been rated as a national high-tech enterprise

SERVICE ASSURANCE

Our company always focuses on customers and strives to improve product quality and service level, with the goal of zero product defects and zero customer complaints

PARTNERS

Our success cannot be achieved without the strong support of every partner

Inquire

Note: Please complete this form, and we will contact you by the next business day.