Newest Automated Production Line For Glass Fiber Continuous Winding Pipes

The integration of state-of-the-art controls allows for real-time monitoring and adjustments during the winding process, ensuring that every pipe meets stringent quality standards. This not only enhances product reliability but also contributes to the sustainability of the manufacturing process by minimizing waste and optimizing material usage. As we emphasize on the keyword "Automated Production Line for Glass Fiber Continuous Winding Pipes," it's evident how this technology aligns with the modern demand for eco-friendly and efficient production solutions.

The integration of state-of-the-art controls allows for real-time monitoring and adjustments during the winding process, ensuring that every pipe meets stringent quality standards. This not only enhances product reliability but also contributes to the sustainability of the manufacturing process by minimizing waste and optimizing material usage. As we emphasize on the keyword "Automated Production Line for Glass Fiber Continuous Winding Pipes," it's evident how this technology aligns with the modern demand for eco-friendly and efficient production solutions.

Furthermore, the versatility of our automated production line is a standout feature, accommodating a variety of pipe diameters and thicknesses effortlessly. This adaptability makes it an invaluable asset for manufacturers seeking to expand their product range without incurring additional hefty investments in specialized equipment. By simply adjusting the parameters, producers can seamlessly transition between different pipe specifications, thereby enhancing their market responsiveness and customer satisfaction.

In conclusion, the Automated Production Line for Glass Fiber Continuous Winding Pipes epitomizes the future of pipe manufacturing. It encapsulates the essence of automation, delivering superior quality, efficiency, and adaptability. As we reiterate the significance of our keyword throughout, it becomes clear that this technology is not just a tool but a catalyst for transforming the way we manufacture glass fiber pipes. Embrace innovation and elevate your production capabilities with a system designed to meet tomorrow's challenges head-on.

WHY CHOOSE US ?

STRENGTH

The group currently has a standard factory area of over 20000 square meters and an annual production capacity of around 100 sets of pipeline equipment

INNOVATION

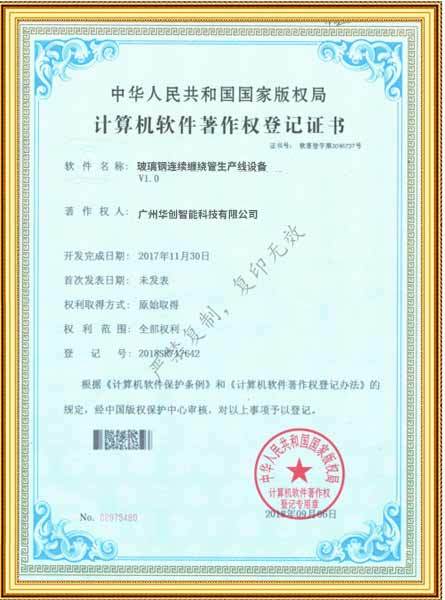

Since its establishment, the company has continuously carried out technological innovation and industrial upgrading, and has been rated as a national high-tech enterprise

SERVICE ASSURANCE

Our company always focuses on customers and strives to improve product quality and service level, with the goal of zero product defects and zero customer complaints

PARTNERS

Our success cannot be achieved without the strong support of every partner

Inquire

Note: Please complete this form, and we will contact you by the next business day.