Pipes Production Line

lt adopts high precision passive aluminum on line forming machine with welding effect testing system,guarantee the high roundness and precise dimensions.

Main technical charateristics

lt adopts high precision passive aluminum on line forming machine with welding effect testing system,guarantee the high roundness and precise dimensions.

The outer plastic-glue and inner plastic-glue adapts two step co-extrusion technology,improves theplastic-aluminum adhesion quality, and make it much easier to adjust and start the production, as well asdifferent sizes shift.

On line air pressure testing device tests if the welding strengthen qualified.

lt adopts PLC control system and HMl for whole extrusion line, synchronization function realized. lt helpsthe group machine production management and quality control.

Main technical parameters

| Type | Pipe Size(mm) | Max.Speed(m/min) | Total Power(kw) | Total Length(m) |

| SLAP-CH32 | Φ16~Φ32 | 12 | 95 | 40 |

| SLAP-CH63 | Φ40~Φ63 | 5 | 180 | 48 |

| SLAP-CH110 | Φ75~Φ110 | 2 | 220 | 60 |

The Pipes Production Line is designed for high-efficiency manufacturing of pipes across various industries. With cutting-edge technology and advanced automation, this production line ensures consistent quality and precise pipe production at high speeds. Ideal for producing a wide range of pipes, including PVC, HDPE, and steel, the Pipes Production Line offers flexibility to meet diverse industry needs.

Equipped with advanced extrusion systems, the Pipes Production Line guarantees smooth, uniform pipes that are built to last. The fully integrated system includes automatic feeding, cutting, and cooling processes, streamlining production and minimizing waste. Additionally, the line is optimized for energy efficiency, making it both cost-effective and environmentally friendly.

The Pipes Production Line is customizable to meet the specific requirements of your business. Whether you're producing large quantities of pipes for construction projects or specialized pipes for niche applications, this production line adapts to your needs. With precise control over pipe diameter, thickness, and material composition, the Pipes Production Line delivers high-quality products every time.

WHY CHOOSE US ?

STRENGTH

The group currently has a standard factory area of over 20000 square meters and an annual production capacity of around 100 sets of pipeline equipment

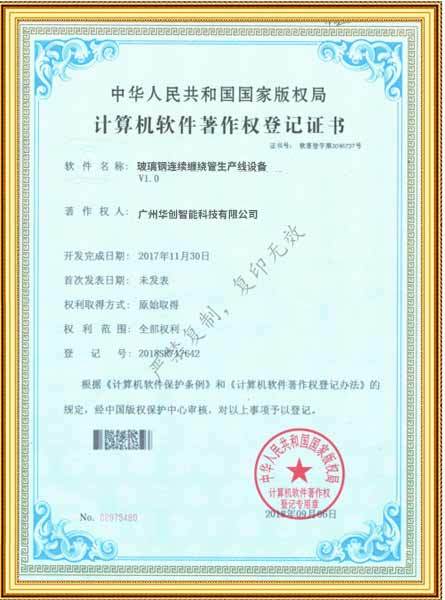

INNOVATION

Since its establishment, the company has continuously carried out technological innovation and industrial upgrading, and has been rated as a national high-tech enterprise

SERVICE ASSURANCE

Our company always focuses on customers and strives to improve product quality and service level, with the goal of zero product defects and zero customer complaints

PARTNERS

Our success cannot be achieved without the strong support of every partner

Inquire

Note: Please complete this form, and we will contact you by the next business day.