Grp Production Line

lt adopts high precision passive aluminum on line forming machine with welding effect testing system,guarantee the high roundness and precise dimensions.

Automated Production Line For Glass Fiber Continuous Winding Pipes:

An Automated production line for glass fiber continuous winding pipes is a remarkable innovation in the manufacturing industry. This state-of-the-art production line is designed to streamline and optimize the production process of high-quality glass fiber continuous winding pipes.

The key features of this automated production line include advanced technology and precision engineering. It ensures consistent quality and uniformity in the production of glass fiber continuous winding pipes. The automated system precisely controls the winding process, guaranteeing the pipes have the desired strength and durability.

Throughout the production line, the keyword “glass fiber” is prominently featured. The high-quality glass fiber used is the core material, providing excellent mechanical properties and resistance. The “continuous winding” technique is another crucial aspect, allowing for seamless and efficient pipe formation.

Main technical parameters

| Type | Pipe Size(mm) | Max.Speed(m/min) | Total Power(kw) | Total Length(m) |

| SLAP-CH32 | Φ16~Φ32 | 12 | 95 | 40 |

| SLAP-CH63 | Φ40~Φ63 | 5 | 180 | 48 |

| SLAP-CH110 | Φ75~Φ110 | 2 | 220 | 60 |

WHY CHOOSE US ?

STRENGTH

The group currently has a standard factory area of over 20000 square meters and an annual production capacity of around 100 sets of pipeline equipment

INNOVATION

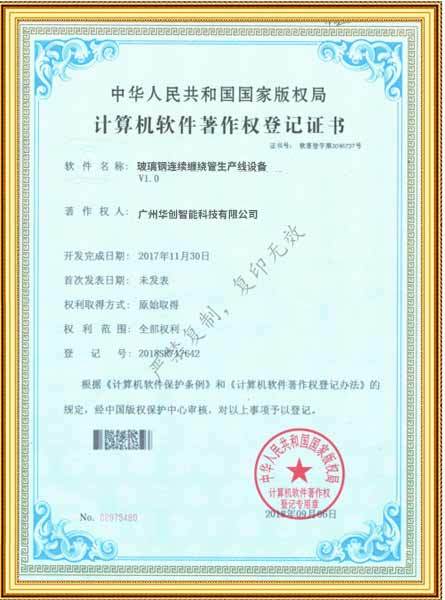

Since its establishment, the company has continuously carried out technological innovation and industrial upgrading, and has been rated as a national high-tech enterprise

SERVICE ASSURANCE

Our company always focuses on customers and strives to improve product quality and service level, with the goal of zero product defects and zero customer complaints

PARTNERS

Our success cannot be achieved without the strong support of every partner

Inquire

Note: Please complete this form, and we will contact you by the next business day.