Problems and countermeasures in the use of glass fiber reinforced plastic pipes

Jul 10,2024

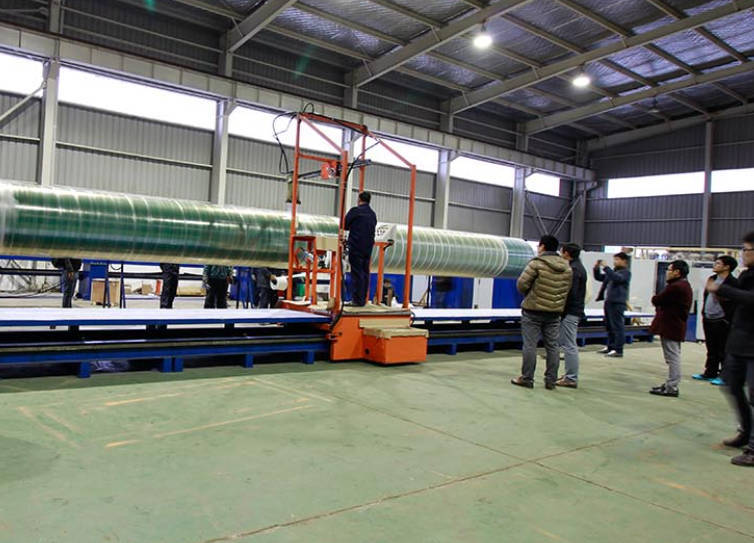

In the past ten years of application in my country, many engineering quality problems have occurred. In order to ensure the quality of the project when using FRP sand-filled pipes, the pipe layer design and production should be carried out on the basis of safe, reliable, reasonable and economical engineering structure design to ensure the quality of the pipes. At the same time, the installation and construction should be organized in accordance with the engineering structure design requirements and construction regulations to meet the control requirements, so as to ensure the success of the FRP sand-filled pipe project.

1 Main problems

FRP sand-filled pipe projects all require strict engineering structure design. In the early stage of domestic use, there is no structural design specification in China, and the design according to foreign specifications lacks long-term performance data of pipes. Therefore, some projects did not pass the engineering structure design. In addition, for economic considerations, the safety factor of the initial circumferential tensile strength of the pipe is relatively low (implemented at 4 times), and due to the influence of raw materials and production processes of FRP sand-filled pipes, the long-term performance test results completed by some domestic companies are slightly lower than the test results of foreign products. In addition, in terms of construction, excessive vertical deformation often occurs, causing the pipeline to be damaged by excessive external pressure load during the working stage, resulting in engineering quality problems. Therefore, there are two major problems in the engineering structure design, namely, the safe and reasonable initial hoop tensile safety factor and the reasonable backfill material and vertical deformation control requirements.

The main problems in pipe materials are the selection of raw materials, the amount of glass fiber and the production process. Some manufacturers use low-performance cheap resins and high-alkali glass fibers to produce FRP sand-filled pipes, and the production process cannot ensure the density of the resin mortar layer. The performance of such FRP sand-filled pipes is far from the product standard requirements, but such pipes have been found in multiple projects.

In terms of construction, often because the construction unit is accustomed to the construction of concrete pipes, usually do not pay attention to the backfill density, which will cause excessive vertical deformation of the pipeline and cause pipe damage.

2 Countermeasures

2.1 Engineering structure design

Glass fiber reinforced plastic sand-filled pipes have been used in my country for more than ten years. The "Design Code for Pipeline Structure of Buried Glass Fiber Reinforced Plastic Sand-filled Pipes in Water Supply and Drainage Projects" (CECS190: 2005), which was completed on the basis of many years of domestic application, is the specification that should be followed in the design of domestic glass fiber reinforced plastic sand-filled pipe engineering structures. Considering the safe, reliable and reasonable and economical use of glass fiber reinforced plastic sand-filled pipes, it is recommended that the long-term vertical deformation of glass fiber reinforced plastic sand-filled pipes should not exceed 3% during design.

2.2 Pipe quality

To ensure the quality of pipes, the following aspects should be paid attention to:

1. Raw materials

According to the product standard requirements, the technical indicators of raw and auxiliary materials used in production should be specified accordingly: alkali-free glass fiber should be used; structural layer resin: tensile strength: 60MPa; tensile elastic modulus: 3.0GPa; elongation at break: 2.5%; thermal deformation temperature: 70℃. It is stipulated that raw material manufacturers should test all raw materials and put them into use only after they are qualified. For important raw materials such as glass fiber and resin, they should be used only after they are qualified by third-party sampling.

2. Production monitoring

For the production process of pipes, it is advisable to ask professional units to supervise the production to ensure the sufficient use of main raw materials.

3. Product acceptance

Products must undergo strict inspection before leaving the factory. In addition to non-destructive inspection of each pipe, one pipe in each batch (generally 100 pipes per batch) should be randomly selected for destructive inspection to ensure the quality of the pipes.

In fact, when determining the pipe production enterprise, enterprises with large production scale, more application performance, strong technical force and good financial situation should be selected to undertake the pipe production business.

2.3 Construction

In the construction of FRP sand-filled pipes, the design requirements should be followed, the appropriate backfill materials should be selected, and the backfill density should be strictly controlled. Only when the density requirements are met can the vertical deformation of the pipe be controlled, and the tensile stress level of the pipe wall can be controlled. In this way, the maximum tensile stress level of the pipe wall will not be too high after the internal water pressure acts, and it can operate safely. In addition, the selection of sealing rubber ring materials, interface connection design, and prevention of uneven settlement at the connection with the building should also be handled with caution.

2.4 Project management

In fact, for any project to be successful, the organization and management of the project construction unit is the most fundamental guarantee. The project structure design should be reliable and reasonable. If the selected design unit lacks experience in FRP sand-filled pipe engineering, relevant professional units should be consulted. The production process of pipes should also be strengthened to ensure that the raw materials and production processes used meet the requirements, and professional units can be hired for supervision. During the construction phase, the test section or the advance section can be constructed first, and the design and construction regulations can be met, and the relevant personnel can have a corresponding understanding of the characteristics of FRP sand-filled pipes, and then large-scale construction can be carried out. At each implementation stage, once a problem may affect the quality of the project, the construction management unit should clearly require corrections. Only in this way can the quality of the project be guaranteed.

PREVIOUS:

NEXT:

Contact Us

E-mail:

Phone/Wechat/WhatsApp

Address:

A2-1408, Kaichuang Avenue to Tai Plaza, Huangpu District, Guangzhou City, Guangdong Province